What Should You Prepare When Automating Your Factory

Companies spend a big chunk of their money on things that affect their business. It could be for operational cost, local and overseas business expansion, mass hiring of talent, supply replenishment, and equipment upgrades. There are even companies that take capital loans to sustain these needs.

A massive equipment upgrade and factory automation require thousands and millions of money. That is why the plan should be well-thought about, or else the new tools and equipment like a positioning sensor, lidar sensor, and rotary encoder will be in vain.

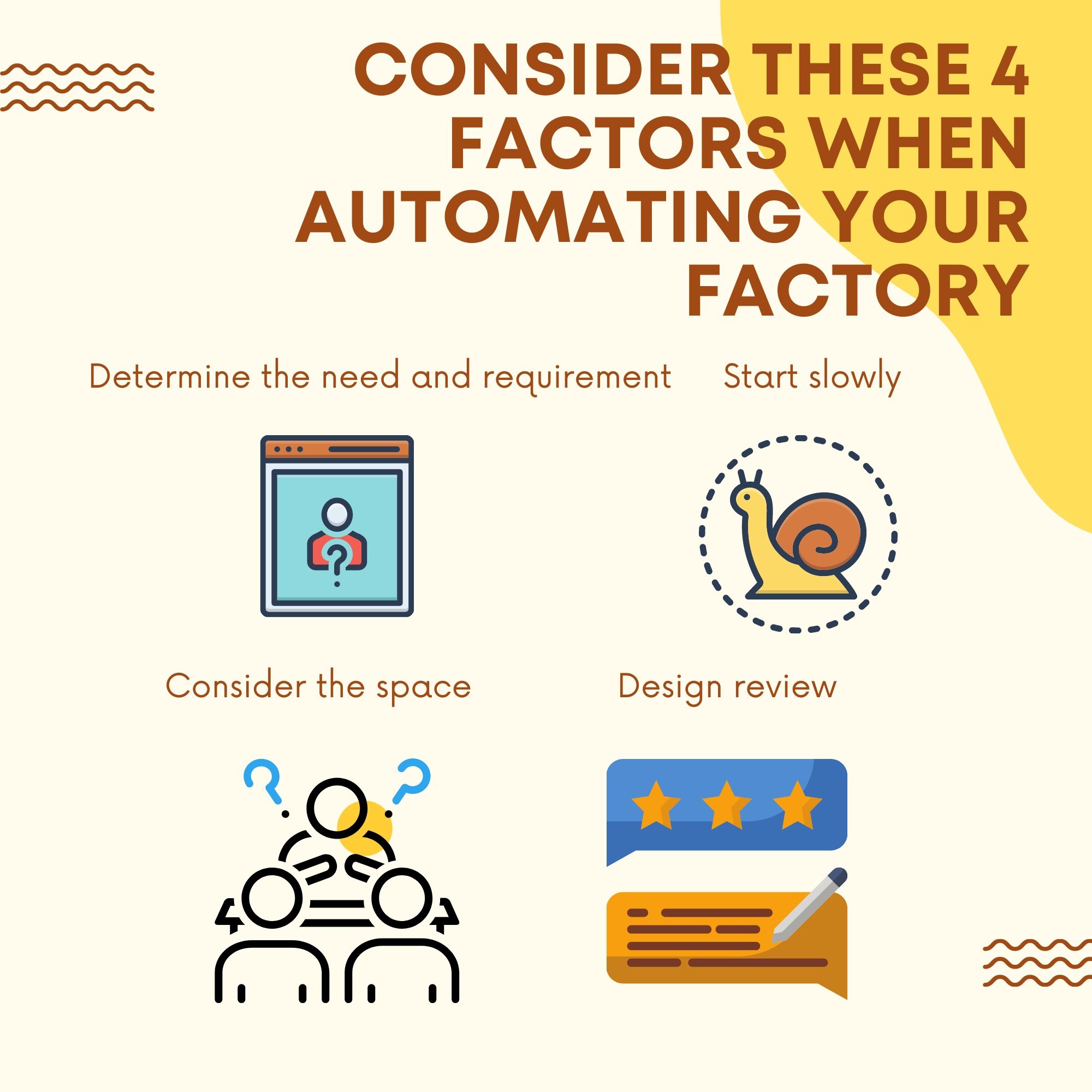

Here are the things to consider before automating your factory:

- Determine the need and requirement

There is nothing more exciting than automating your factory. Equipment upgrade guarantees reduced cost and downtime. But eventually, the upfront cost is not easy as well. Some businesses start their upgrades gradually by selecting a single manufacturing area that needs more help before proceeding to others.

For example, the factory may automate the item assembling process by purchasing equipment and tools like a positioning sensor and leave the packaging in manual work for the meantime.

- Start slowly

The downside of automating the entire factory is that the staff and technical teams get overwhelmed. Gradual upgrades help them to familiarise themselves with the new automated process at a time. So when the next upgrades arrive, they know too well how to operate a rotary encoder before moving on.

- Consider the space

Humongous machines are expected in a large scale manufacturing and production process, taking ample space. Most businesses coincide the phase property expansion with the equipment upgrade. When purchasing new equipment like a lidar sensor, make sure the factory has space for it.

- Design review

Not all processes are the same. Generic equipment may not work with the unique needs of your products. The company's engineers and tech team need to conduct a design review on the equipment. Some equipment manufacturers allow the custom design of equipment or alterations to a machine and rotary encoder.

Automating your factory brings a lot of benefits. Maybe it is time for you to have one.

Pepperl+Fuchs is committed to helping businesses automate their production. Visit Pepperl+Fuchs today.